SEARCHER

- -- Precision Metal Welding System

- -- Resistance Welding Consumables & Accessories

- -- High Speed Automatic Cutting System

- -- Ultrasonic Plastic Welding System

- -- Automatic Welding System

Machine & Accessory

- Expert design and supply of..

- Specially low resistance pu..

- DANPS Nickel Plated Steel S..

- Electrode selection for res..

- Herbert Resistance Welding ..

- LOREA NA180 Nickel Alloy is..

- Expert design and supply of..

- Computerized Automatic High..

- Selective Tin Plating Phosp..

- Computerized Automatic High..

News

Product Show

Home >> Metal >> Electroplated Metal Strips >> Nickel Plated Copper (NPC)

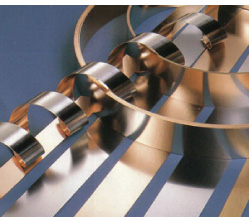

Nickel Plated Copper (NPC)

Nickel Plated Copper (NPC)Detail

Nickel Plated Copper Strips (NPC)

The nickel plated copper strip of HIMAX is excellent in quality. Himax adopts high quality copper strips as base material, and electroplated by Canada INCO nickel squares (Ni>99.9%). By implementing Himax unique annealing and post metal treatments processes, Himax’s NPC is guaranteed to have excellent bending tolerance and maximum electrical conductivity. NPC is mainly used in making terminals / contact plates of Li-ion battery, NiMH battery, Lithium battery, mobile phone battery and high current battery packs.

Common specifications of NPC, Himax also accepts customized specifications:-

|

Name |

Common thickness |

Base material |

Plating layer |

Hardness |

E. Resistivity |

|

Nickel plated copper strip (NPC) |

0.1mm / 0.15mm / 0.2mm / 0.25mm / 0.3mm |

Copper C1100

(Cu>99.9% ) |

>2um

(By INCO nickel squares) |

HV60-80 |

< 1.8μΩ‧cm |

Supply of Different Kinds of NPC

In order to match different usage, Himax is able to supply NPC in two categories:-

(A) Slit-After-Plating NPC – the slitting edges do not plate with nickel, hence the production cost is relatively lower.

(B) Plating-After-Slit NPC – both sides and slitting edges plate with nickel to ensure full nickel coating protection. Hence the production cost is relatively higher.

Able to Choose Base Material in Different Country of Origins

Users are able to choose either Japan imported copper strips or China copper strips for the base material of NPC according to their applications and cost plans.

Outstanding Bending Tolerance

With Himax unique electroplating line, we are able to implement special plating, annealing and treating processes, as to complete avoid the copper strip becomes brittle after nickel plating. Himax’s NPC is equipped with maximum 8 times 180° bending tolerance property.

Precision Deburring Process

HIMAX owns several high precision deburring machines, which are able to erase all shaped edges of copper strips before nickel plating. After deburring process, the NPC can be used without damaging the battery material and avoid the leakage problem.

Strictly Compliant on Environmental Rulings

Himax NPC is strictly compliant with RoHS and SGS independent testing report can be provided.

Welcome Orders in Small Quantity, Rapid Delivery

Himax welcomes all kind of orders, either in small quantity. Our delivery lead time is quick, normally 10-15 days will be completed.

Previous:Tin Plated Steel / Copper Strips (TPS/TBC)Next:Copper Nickel Plated Steel (CNPS)