SEARCHER

- -- Precision Metal Welding System

- -- Resistance Welding Consumables & Accessories

- -- High Speed Automatic Cutting System

- -- Ultrasonic Plastic Welding System

- -- Automatic Welding System

Machine & Accessory

- Selective plating Service

- Computerized Automatic High..

- Diffusion annealing Nickel ..

- Micro-weld Resistance weldi..

- Micro-weld Resistance weldi..

- DANPS Electro-nickel Plated..

- Precision metal stamping fa..

- Selective Tin Plating Batte..

- DANPS Nickel Plated Steel S..

- Computerized Automatic Tab ..

News

Product Show

Home >> Machine & Accessory >> Precision Metal Welding System >> Weld Head (Air or Manual Actuted)

Weld Head (Air or Manual Actuted)

Weld Head (Air or Manual Actuted)Detail

MICRO®-WELD WELD HEAD SERIES

(A) High performance, durability and long life

Himax Micro®-Weld weld head series consist of two main categories: air actuated and manual actuated, which provide high performance for precision metal joining. Micro®-Weld Series are precision, low inertia, force-fired designs with a narrow vertical profile. They are ideal for both production line and bench applications and can operate at speeds greater than 3600 welds per hour.

(B) Low inertia design

Micro®-Weld weld heads excel in their ability to precisely place consistent, high quality welds, even in complex welding applications. Their low inertia designs ensure the fast dynamic response required for the electrodes to follow the minute expansion and contraction of the weld joint as it heats and cools. A differential motion force-firing system initiates tile welding control at the precise moment when the pre-set electrode force is applied to the workpieces.

(C) Prefect bearing system

Rugged construction, linear ball bearing bushings and an over-sized, anti-rotation bearing system provide perfect in-line electrode travel of the upper electrode arm. This system virtually eliminates the wiping action of the electrodes during welding, even at maximum force settings. Based on actual test data, bearing life exceeds 25 million operations when used according to the specifications.

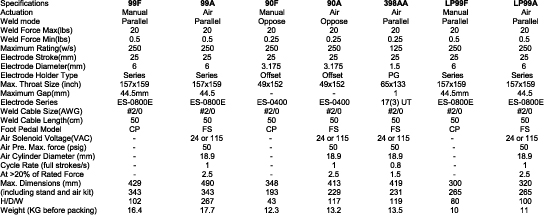

(D) Our common models of weld head:-

(E) Excellent performance on automation welding system

A top-mounted air actuation system, with a regulator and dual flow controls, insures repeatable, reliable, high-speed operation in automated applications. Threaded holes on the back of the heads make them easy to mount, without their post or base, in automated work stations.

(F) Main FEATURES

- Adjustable FORCE-FIRING

- Rugged design

- Low Inertia Design

- Air Actuation Option

- Adjustable Tare Spring

- Single Air Regulator

- Up to 1.5 inch Stroke.

- Up and Down Stops.

(G) Unique outstanding BENEFITS

- Permits high quality, precision small parts welding since welding force is independent of the electrode stroke

- Improves productivity, minimizes repair costs and ensures long life

- Improves weld consistency, reduces metal expulsion and improves the appearance of the weld

- Integrates easily into automated work stations and provides rates of one weld per second at maximum weld force

- Allows use of custom electrodes without sacrificing performance

- Simplifies adjustment and increase speed of air actuated heads

- Allows welding inside deep cavities

- Increases production rates by allowing user to optimize the motion of the upper electrode.

Previous:Common battery tabsNext:Metal Parts Plating Service